Challenges and Opportunities Facing the Chinese Cable Industry: An In-depth Analysis

Over the past five years, China’s cable industry has undergone remarkable development and transformation. According to relevant statistics, the domestic cable market size has grown at an average annual rate of approximately 8% during this period, reaching hundreds of billions of yuan by 2023. With the continuous advancement of domestic infrastructure construction, the demand for cables in fields such as power, communications, and transportation has continued to increase. For instance, in the power sector, the annual demand for cables due to the newly added installed power generation capacity amounts to several million tons. During this period, the industry scale has been expanding continuously, and there are a large number of enterprises. According to industry reports, as of 2023, there are over a thousand cable enterprises above designated size.

Technological innovation has become a key factor in enterprise competition. Some large enterprises have increased their investment in research and development, and the proportion of R&D expenditure in sales has increased year by year. Some enterprises have even reached more than 5%. The continuous introduction of new high-performance cable products, such as high-voltage and ultra-high-voltage cables, and special cables, has met the special needs of different fields. At the same time, the concept of environmental protection has gradually gained popularity, and the cable industry is also striving to develop in the direction of green production. According to incomplete statistics, the proportion of enterprises adopting environmentally friendly materials and production processes has increased from 30% five years ago to over 50% now. However, the industry development also faces some challenges.

The fluctuation of raw material prices has brought significant pressure on cost control for enterprises. Take copper as an example. Over the past five years, its price fluctuation range has exceeded 30%, directly affecting the cost and price of cable products. In addition, some small and medium-sized enterprises are at a disadvantage in market competition due to relatively backward technology levels and serious product homogeneity. It is estimated that about 10% of small and medium-sized enterprises have been eliminated in the past five years. In the international market, the export volume of Chinese cable products has gradually increased, and the average annual growth rate of export value has reached approximately 10%. However, it also faces issues such as international trade barriers and differences in technical standards. Some developed countries have higher requirements for the quality and performance of cable products. For example, the European Union has strict regulations on the fire resistance and environmental protection standards of cables.

Under the current situation, in order to cope with various challenges and opportunities, China’s cable industry urgently needs to introduce the latest technical equipment. According to market research, advanced automated production lines can increase production efficiency by more than 30%, reduce errors caused by manual operations, and the product qualification rate can be increased from 90% to over 95%. At the same time, new energy-saving equipment can reduce energy consumption by approximately 20%, further reducing production costs.

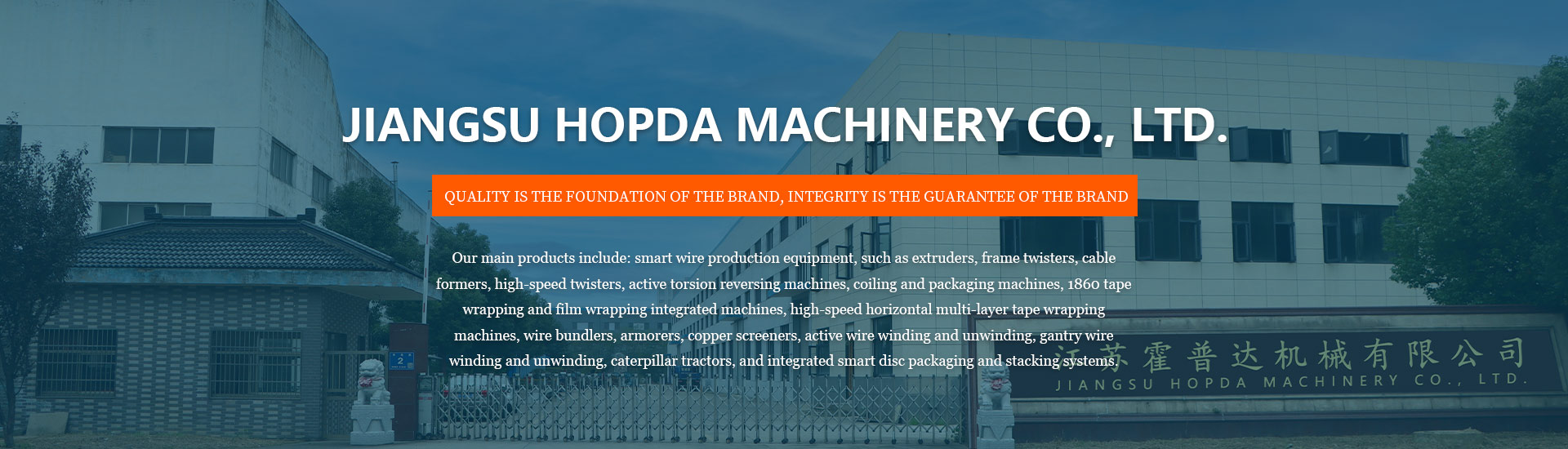

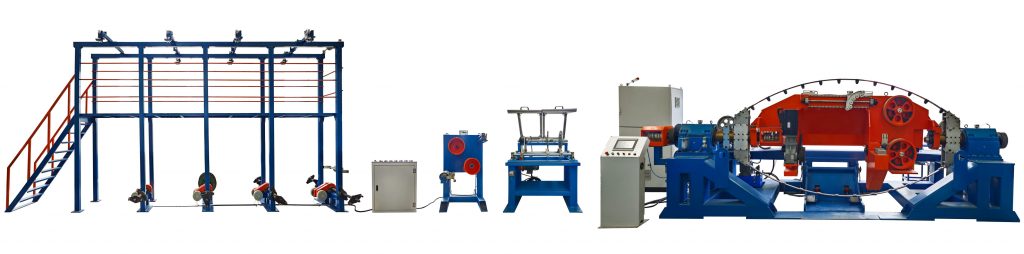

Moreover, the latest technical equipment has more powerful functions and higher flexibility. For example, it can produce cables with smaller diameters and higher performance, meet diverse market demands, and help enterprises explore new market segments. Jiangsu hopda Machinery is an expert manufacturer of the latest cable equipments. One of our flagship products is 1250/1600 double-twist stranders which is a replacement for the traditional tubular stranders. The productivity of our machine is 3 times that of the conventional tubular stranders, leading to a huge cost advantage for our clients over other competitiors. Another star product of ours is the 1860 coiling machine which integrates cable winding, strapping, wrapping and robot stacking functions. It is a real game changer when it comes to labour saving.

In conclusion, over the past five years, China’s cable industry has experienced both development and challenges. Under the current situation, the introduction of the latest technical equipment is of crucial significance for reducing production costs, improving productivity, and promoting the sustained and healthy development of the entire industry.

English

English Русский

Русский